KROWN

Krown

Melting furnaces for aluminium foundries

Integral services for the design and manufacturing of aluminium foundry furnaces

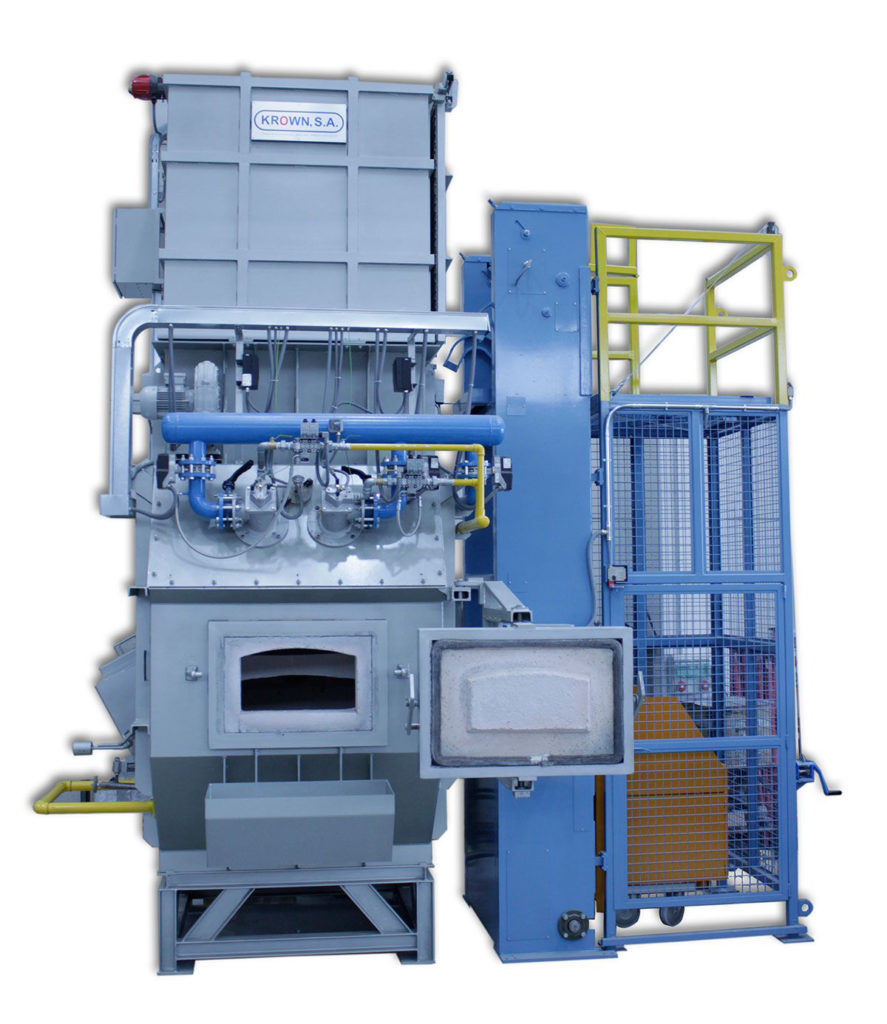

TOWER MELTING FURNACES

Tower melting furnaces

Krown's tower melting furnaces ensure the lowest aluminium loss and energy consumption, as well as the best production conditions for aluminium foundries, optimising the process and guaranteeing the metal quality required for the manufacture of even structural castings.

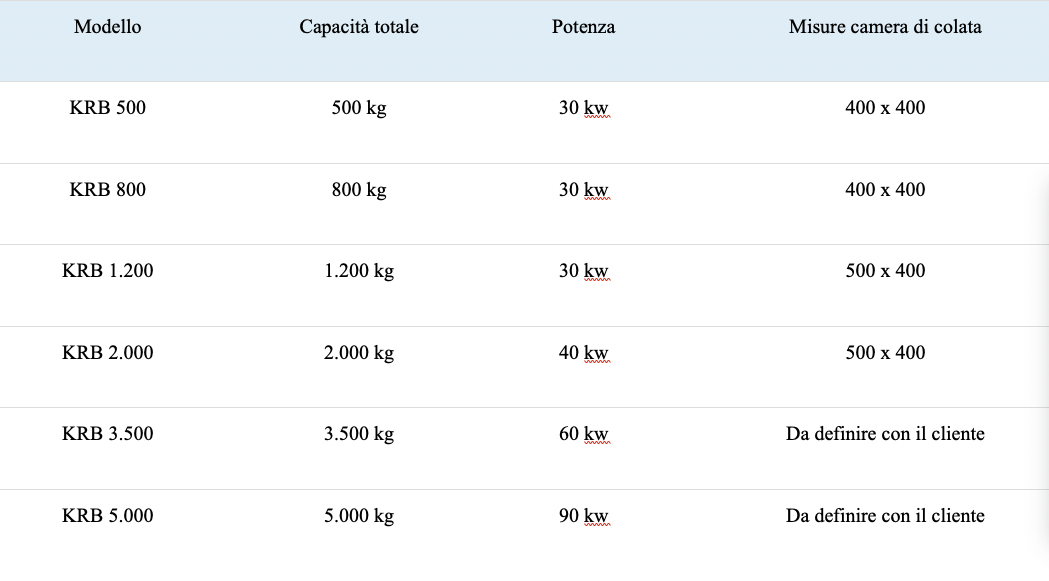

We have several models of tower melting furnaces with holding capacities from 750 to 6,000 kg and melting capacities from 350 to 4,000 kg.

FEATURES

Tower melting furnace with superposed chambers

Tilting Tower Melting Furnace

Download Data SheetHOLDING FURNACES

TRANSPORT LADLES

Transport ladles

The ladles produced by Krown SA are made of perfectly insulated refractories and are equipped with a lid to reduce temperature losses and ensure the safety of operators during the transport of aluminium from the melting furnace to the holding furnace.

We have several models with load capacities from 320 to 960 kg:

Download Data Sheet