WOLLIN

Wollin

Foundry spraying systems

Die-casting mould spraying systems

Wollin GmbH was founded in 1980 by engineer Rudolf Wollin, and supplies lubrication and automation systems in more than 40 countries worldwide. Approximately 70 employees, qualified and experienced in design, production and service, ensure continuous development of the products to suit all foundry requirements. Thanks to the quality of this work, the Wollin name enjoys an excellent reputation in Italy and the rest of the world.

Gefond has represented Wollin since 1998 and to date has sold more than 300 systems in Italy, also providing high-quality consulting, design and service.

WOLLIN DIE SPRAYING MACHINES

Wolin sprayingsystems offer several advantages:

Wollin spraying machines use control panels. The PC3 Process Control was developed for use in die-casting foundries, and enables efficient use and operation of ESM lubricators.

Download Data SheetThere are 2 types of Wollin die spraying machines:

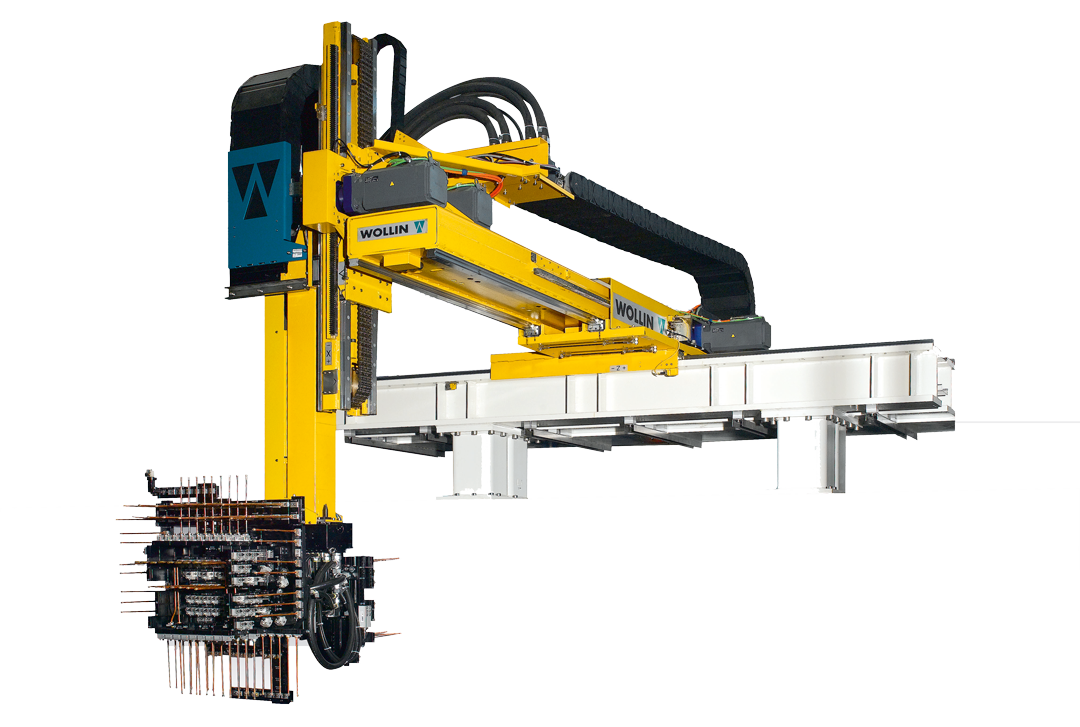

Wollin ESM spraying machines

Wollin ESM lubricators are designed for presses from 160 up to 6200 tons. The harsh working conditions in the foundry were fully taken into account during the design phase. ESM lubricators are supplied in both single-axis and 2-axis versions. They have the option of using 2 different release agents (traditional water-based and concentrated). They use a minimum of 4 to a maximum of 8 lubrication circuits and are always equipped with 2 separate high-pressure blowing circuits. The weight of the lubrication head can range from a minimum of 45 kg to a maximum of 200 kg.

Wollin ESMT lubricators

The Wollin ESMT lubricators (telescopic version) are designed for presses from 560 up to 6200 tonnes and are a viable alternative if there are problems with low sheds or overhead travelling cranes, or other issues concerning the height of the equipment. They have the possibility of using 2 different release agents (traditional water base and concentrate). They use a minimum of 6 and a maximum of 8 lubrication circuits and are always equipped with 2 separate high-pressure blowing circuits. The weight of the lubrication head can range from a minimum of 130 kg to a maximum of 280 kg.

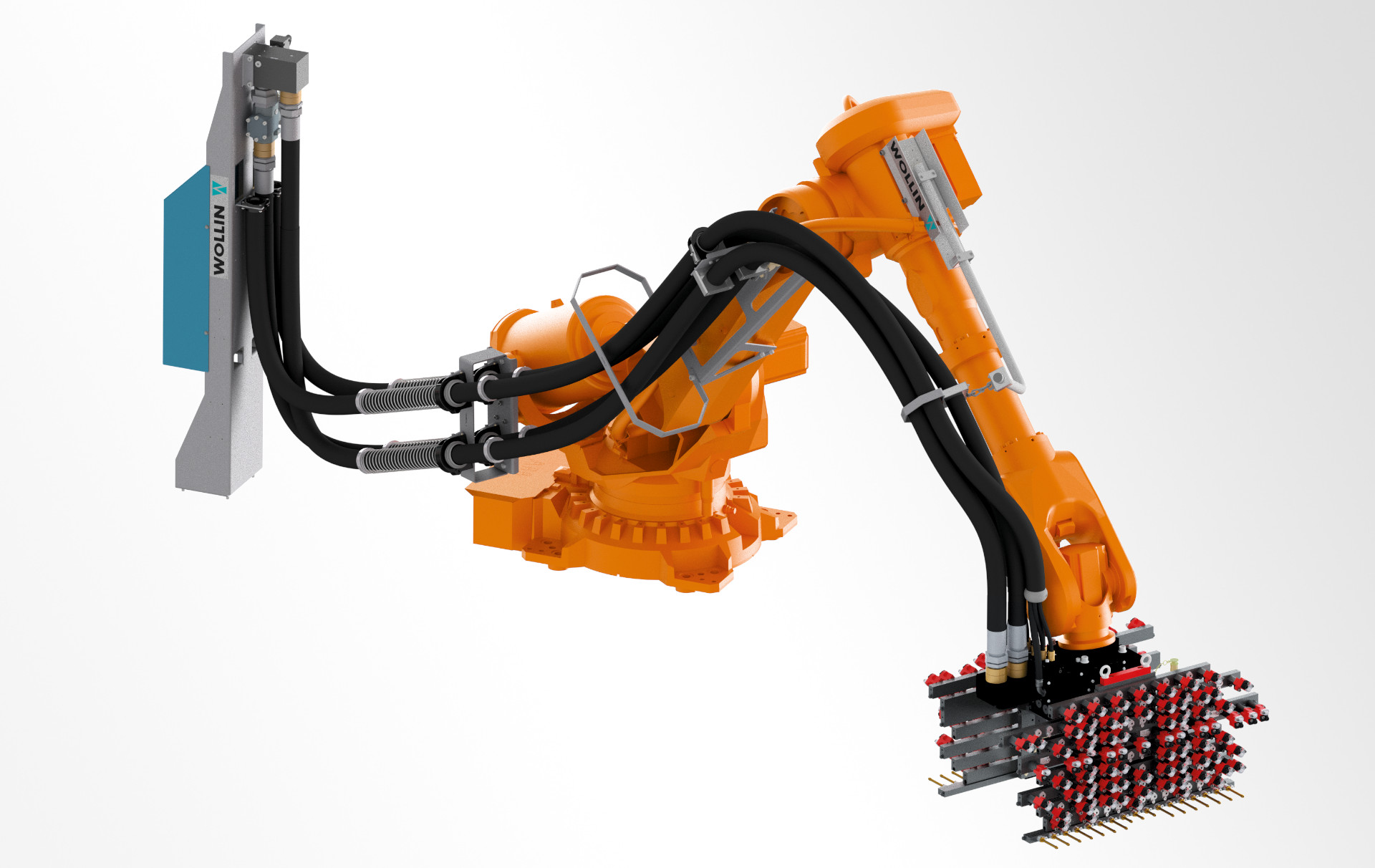

ROBOT DIE SPRAYING SYSTEM

Wollin offers the possibility of using lubrication robots. This type of application gives the possibility of many customisations according to production requirements, so it is advisable to ask us for advice to define the most suitable system. Wollin's robot lubrication systems are available in 2 versions and different sizes depending on the application and size of the die-casting machine.

Download Data SheetEfficient Spray Robot Systems PSR FS with 'linear' lubrication heads

All lubrication heads are equipped with 2 additional circuits for high-pressure blowing (for drying and cleaning the mould in the shortest possible time). Lubrication heads for PSR systems can be extended using standard modules, although the maximum number of nozzles cannot be exceeded.

SPRAYING TOOLS

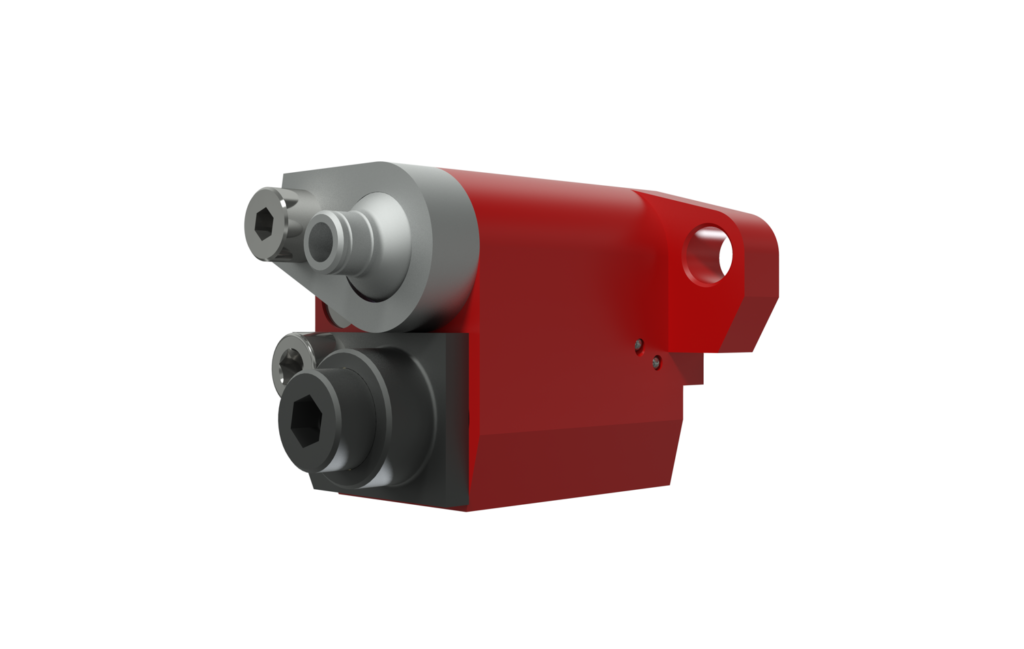

Modular spraying tools heads PS16 - PS25

Modular spraying tools heads provide multiple advantages in the die-casting cycle:

With this method, our customers have achieved considerable cost reductions and increased productivity:

- Easy assembly (Modules for changes in length, width and height).

- Flexibility (Fast change-over times, Flexibility ensured by free configuration of spraying strips, Configuration and optimisation for even complex moulds in a short time).

- High Performance (High flow rates of release agent and air for nozzle supply).

- Process stability (High process stability and reproducibility due to permanent fixing of all mould-specific adjustments).

- Economical (Thanks to the standard PowerSpray system modules, all parts can be reused).

Download Data SheetECO SPRAY - microspray technology

ECO+ SPRAY - microspray technology

The presence of new concentrated or oil-based release agents on the market required the development of a technology that would allow their precise application in minimum quantities. ECO+ SPRAY technology is the result of years of research in this regard and allows highly flexible implementation on a wide range of mould types:

Advantages of ECO+ SPRAY technology:

ECO+ SPRAY technology is based on the use of DDV nozzles (with a volumetric pulse system), which allow the application of quantities ranging from 0.0125 to 0.119 ml. DDV nozzles are compatible with the modular PS16 and PS25 lubrication heads, which guarantees their ease of application and use.

Download Data SheetOriginal spare parts and technical service