Foundry equipment

Foundry equipment

Products and services serving the modern foundry

Technologically advanced foundry equipment

Gefond supplies leading diecasting customers and has been distributing technologically advanced light alloy foundry equipment since 1994.

Gefond has won trust for the quality of its products and reliable and flexible technical support.

Gefond's challenge is to promote cultural change and keep pace with change in the foundry world.

Gefond supports manufacturing industry trends through its innovative technical solutions. Published by the European Commission, the Industry 5.0 report recognizes industry's social role beyond employment and skills development to include sustainability and worker well-being.

Gefond's vision for a long life industry takes shape from these principles and focuses on the values of sustainability, for a more planet-friendly production process, and digitization, to empower workers with more skilled tasks.

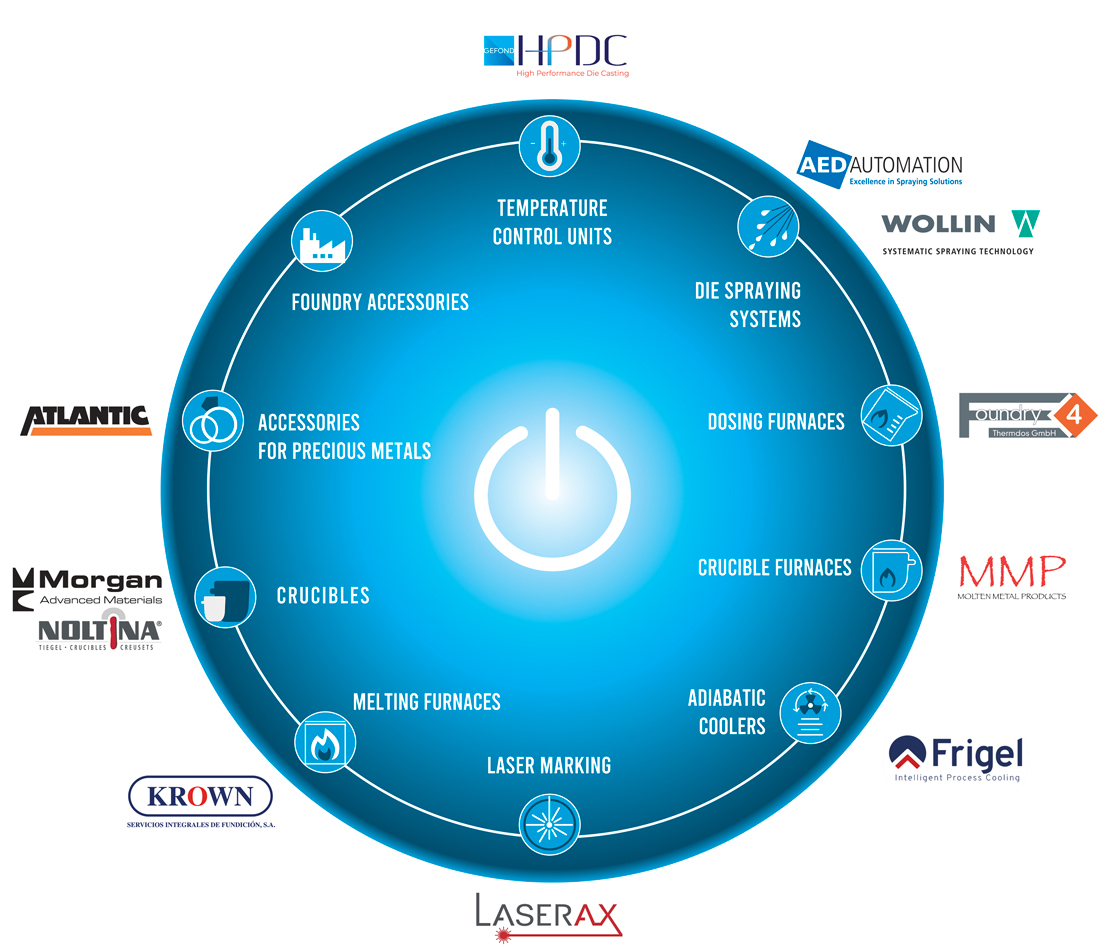

Our foundry equipment and products

Gefond is looking to the future as a leader in the sale of technologically advanced plants, aware of its strategic role for the die-casting industry, which must respond to the need to implement competitive and advanced production processes.

The company recently expanded its offerings by becoming a manufacturer of the innovative and sustainable HPDC by Gefond temperature control units, as well as selling mold lubrication systems, metering furnaces, crucible furnaces and crucibles.

Gefond also supplies melting furnaces, adiabatic coolers and laser markers.

Empowering foundries to exploit the full potential of the cutting-edge technologies it offers is THE goal of Gefond.

A service of training, technical assistance and process optimization completes the proposal designed for the customer.

Revolutionizes the way foundry molds are thermoregulated.

High Performance Die Casting is an innovative startup that produces temperature control units with the goal of changing the way molds in die-casting processes are thermoregulated, saving on energy consumption, reducing CO2 emissions, and improving productivity.

The pressurized water machine uses a unique and patented working method.

The innovative technology consists of targeted and synchronized heat removal on a circuit-by-circuit basis, as opposed to traditional temperature control, which consists of constantly circulating a fluid (water or oil) in the mold at a constant temperature.

Foundry lubrication equipment

World leading manufacturer of lubrication equipment with installations in more than 40 countries worldwide.

Continuous development of the facilities to adapt them to all the needs of foundries is ensured by about 70 employees, qualified and experienced in design, production and service.

Gefond since 1998 and to date has sold more than 300 Wollin plants in Italy, with the added benefit of high-quality consulting, design and service.

Die-casting mould spraying systems

The Cartesian and robot lubricator series are derived from long experience and research aimed at the best performance.

The ideal solution for efficient lubrication in the field of die-casting is The modular concept with high-quality components from AED Automation GmbH (formerly Acheson), which has entrusted Gefond with the marketing of equipment, technical support and distribution of spare parts for its plants in Italy, both for machine spare parts and for lubrication heads and their components.

Aluminium dosing furnaces

Foundry4 is a worldwide manufacturer of the highest quality dosing ovens.

Gefond has sold more than 300 dosing furnaces in Italy over the past 25 years that offer the most efficient technologies on the market, with increased safety and great reliability, low aluminum drop, short process times, dramatic reduction of energy consumption, and improved metal quality.

Energy-efficient crucible furnaces

A manufacturer of a wide range of crucible furnaces, world-leading Molten Metal Products Ltd offers crucible furnaces for melting and holding metal: a complete range of gas-fired electric and recuperator furnaces in both fixed and tilting versions.

First Morgan and now MMP have focused on reducing energy costs by creating a furnace that uses fuel more efficiently leading to significant energy savings.

Cooling chillers for industrial processes

Designed to replace evaporative tower technology Ecodry is a centralized, closed-loop adiabatic cooling system installed outdoors to dispose of heat extracted from processes into the environment.

This leads to better cooling performance with increased heat transfer efficiency, cost savings and lower operating cost, reduced environmental impact, both in water footprint and emissions with up to 95% water savings.

Laser marking systems for die casting

Laser marking solutions for directly and permanently marking components with identifiers, such as data matrix codes, QR codes, serial numbers and logos-this is what LASERAX offers.

Hand-loading laser marking machines are 100% safe machines with a few simple operations such as loading parts and launching the laser marking.

They can be used for multiple applications and are easy to move. They are all set up to work with robots.

Melting furnaces for aluminium foundries

With more than 15 years of experience, Krown offers full-service design and production of aluminum casting equipment.